Computed Radiography (CR)

A digital radiography method that has largely replaced traditional film-based radiography due to its superior image quality, efficiency, and flexibility.

Computed Radiography (CR)

Computed Radiography (CR) is a method of non-destructive testing that offers several advantages for industrial inspections. It provides high image quality, facilitating precise detection of defects and anomalies. Additionally, CR is time-efficient as it eliminates chemical processing and manual development, allowing for instant image viewing and analysis. Today, computed radiography systems are flexible and portable, enabling on-site inspections, and the reusable lightweight phosphor plates reduce waste, making them convenient for fieldwork.

How It Works

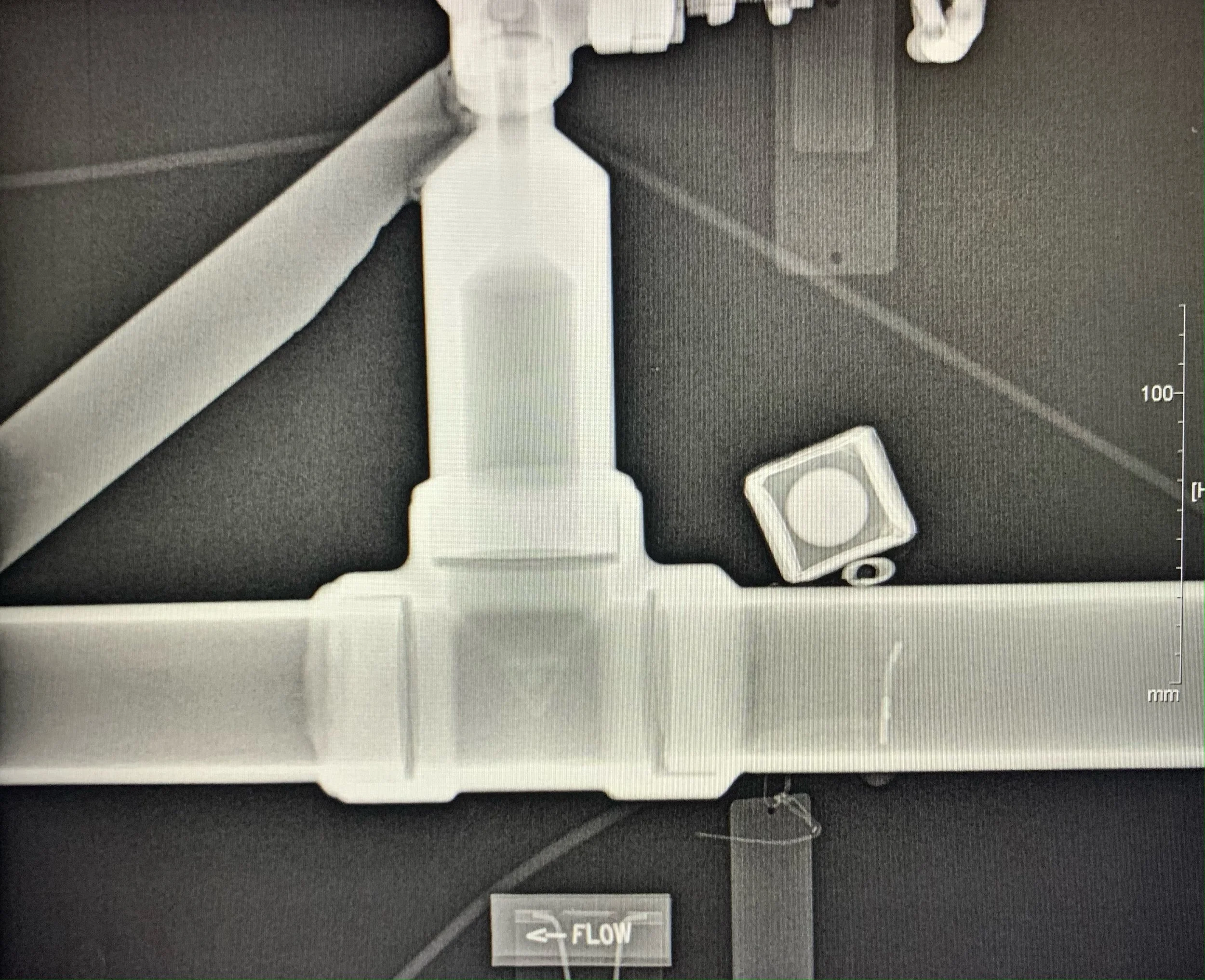

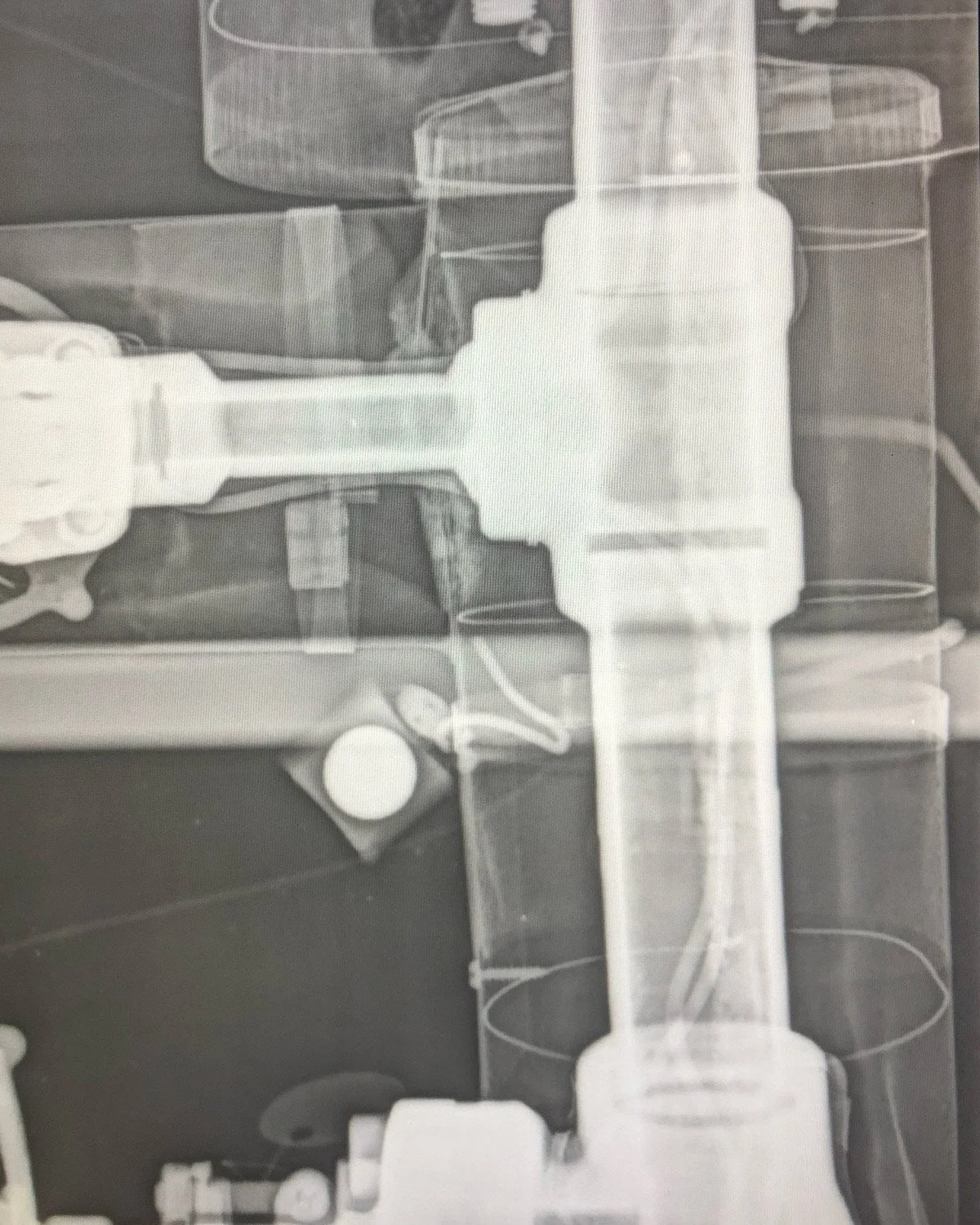

Computed radiography uses a process that involves exposing photostimulable phosphor (PSPs) plates to X-ray radiation. The plates contain a storage material that can absorb X-ray energy. After the picture is taken, a laser scans the plate, causing it to emit light. This light is captured by a detector and turned into a digital image by a computer. This digital image can then be improved and examined further.

The digital images obtained through computed radiography allow for better visualization of defects, accurate measurements, and detailed analysis of assets and components.

We Meet and Exceed Safety and Code Compliances

Safety is paramount to Anode NDT: both our technicians and our procedures prioritize efficiency and safe work practices.

All Anode NDT procedures are ABSA demonstrated and backed with CGSB / ASNT Level III certified support.

We proudly hold ASNT Level II certification.

Our in-house safety program is ISNetworld, ComplyWorks, Avetta, and COR compliant.